Efficient Installation Practices for Steel Buildings: Streamlining Your Building Process

In the world of construction, effectiveness is a cornerstone of success. When it pertains to setting up steel buildings, the procedure can be substantially streamlined by executing efficient installation practices. From meticulous preparation to the use of pre-engineered elements, each step plays a crucial role in expediting the building and construction timeline. Nonetheless, the crucial lies not just in rate however also in accuracy and top quality. By diving into the world of sophisticated installation strategies and making sure rigid high quality control steps, the possibility for enhancing the entire building and construction process comes to be not just an opportunity however a useful reality.

Preparation for Efficiency

When intending to make the most of effectiveness in steel structure setup, thorough planning is crucial. Correct preparation establishes the structure for a well organized and smooth building and construction procedure, inevitably saving time and sources.

Furthermore, efficient communication amongst all stakeholders is extremely important throughout the planning phase. Routine meetings and updates aid maintain everybody on the exact same page, decrease misconceptions, and cultivate a joint working setting - steel buildings. By spending effort and time right into careful planning, steel structure installment can be executed with accuracy and effectiveness

Making Use Of Pre-Engineered Components

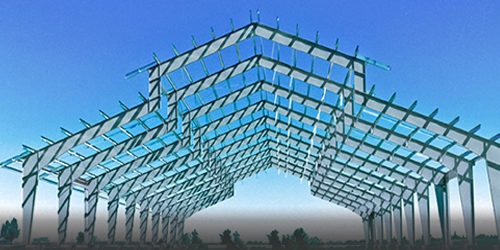

Efficient steel structure setup practices can be additionally improved by leveraging the use of pre-engineered parts. Pre-engineered components are developed and manufactured off-site to precise specifications, ensuring compatibility and simplicity of assembly during the building procedure. By integrating pre-engineered parts such as light beams, columns, trusses, and panels, building contractors can streamline the setup procedure, reduce on-site labor requirements, and minimize building and construction waste.

One key benefit of utilizing pre-engineered elements is the significant time financial savings they use. Because these elements are produced in a controlled setting, they arrive at the building site prepared for quick and reliable installation. This not just accelerates the general building timeline but additionally aids to decrease project hold-ups and connected costs.

In addition, pre-engineered elements are engineered for optimal performance and structural stability, ensuring the lasting longevity and security of the steel structure. By using these standardized elements, contractors can achieve constant top quality throughout various jobs while likewise benefiting from price savings related to reduced product waste and labor expenses.

Maximizing Building Sequencing

To take full advantage of efficiency and effectiveness in steel building installment, strategic optimization of construction sequencing is paramount. By carefully planning the order in which jobs are carried out, construction groups can reduce downtime, minimize material handling, and simplify the general building procedure.

Carrying Out Advanced Installation Techniques

Applying sophisticated setup techniques improves the efficiency and quality of steel building construction this link tasks. By integrating cutting-edge methods such as computer-aided design (CAD) for accurate planning, prefabrication of elements off-site, and use of sophisticated equipment like robotic welders, building and construction teams can significantly streamline the installation procedure. pop over to this web-site CAD software enables detailed 3D modeling, helping in the visualization of the last framework and guaranteeing specific part dimensions for an excellent fit throughout setting up. Prefabrication minimizes on-site labor requirements and building time by fabricating building elements in a regulated setting, lessening mistakes and remodel. The use of robotic welders raises the rate and accuracy of welding tasks, boosting the overall architectural stability of the steel building. Additionally, implementing advanced strategies advertises safety by reducing manual work needs and prospective work environment hazards. By accepting innovation in installment methods, building tasks can be finished faster, with greater top quality results, and within budget constraints.

Making Sure Quality Assurance

Building upon the application of advanced setup strategies, maintaining rigorous quality assurance measures is vital in ensuring the structural stability and integrity of steel building jobs. Quality assurance begins with the choice of top quality products that meet sector criteria and specifications. Routine examinations throughout the construction procedure help identify any type of inconsistencies from the style or possible issues that could jeopardize the building's strength.

Paperwork is a crucial aspect of high quality control, making sure that all action in the installment process stick to the authorized policies and strategies. This includes recording evaluations, material accreditations, and any type of adjustments made throughout building and construction. Applying a clear interaction method amongst staff member and subcontractors aids improve the quality assurance procedure and deal with any type of problems immediately.

Conclusion

In final thought, taking on reliable installation methods for steel structures is critical for streamlining the construction i thought about this process. By meticulously intending, utilizing pre-engineered components, enhancing sequencing, carrying out innovative strategies, and ensuring quality control, building jobs can be finished extra promptly and effectively. These techniques not just conserve time and sources yet likewise add to the general success of the job. It is vital to focus on performance in order to optimize performance and attain effective end results in steel structure construction.

To make best use of performance and effectiveness in steel building installation, strategic optimization of building and construction sequencing is extremely important. On the whole, by maximizing building and construction sequencing, steel structure setup can be completed extra effectively, saving time and costs in the process.

Executing advanced installment methods enhances the efficiency and top quality of steel building construction projects. By focusing on high quality control throughout the installment process, construction groups can provide steel buildings that are not just efficient however also durable and trusted.

In conclusion, taking on efficient setup practices for steel structures is essential for simplifying the building process.

Comments on “Top-Quality Steel Buildings: Sturdy and Flexible Frameworks for Any Kind Of Objective”